Void filler, the definitive ECOLOGICAL solution to avoid the domino effect

THE DEFINITIVE AND ECOLOGICAL SOLUTION TO THE DOMINO EFFECT

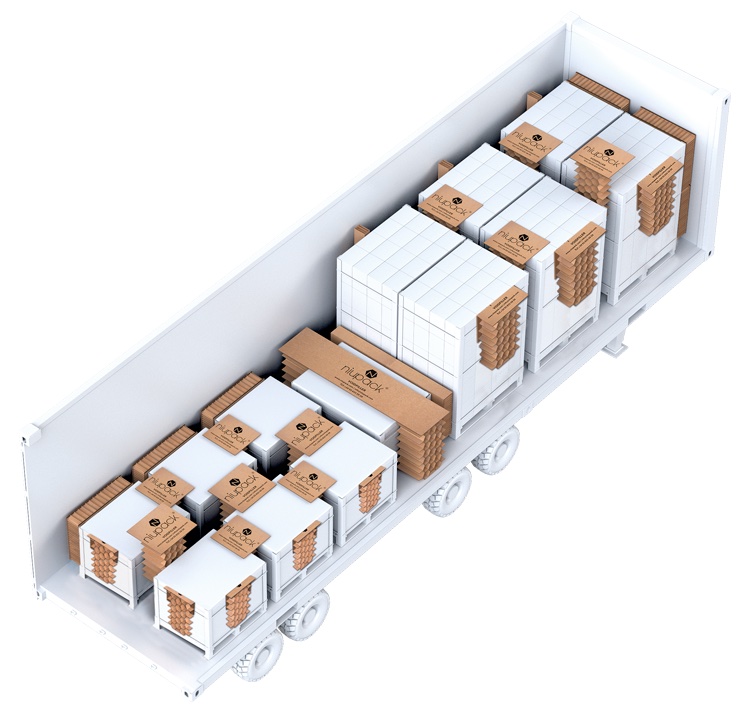

The new and revolutionary void filler to fill the gaps between pallets and prevent the movement of merchandise during transport.

What benefits does Niupack have?

- Unique system in the market.

- Avoid the domino effect that can occur due to braking or acceleration during transport.

- Sustainable and recyclable model, certified by FSC and PEFC.

- Possibility of custom manufacturing.

- Effective and easy to use system.

- Economical, reusable and foldable solution.

Avoid cargo movement during transport

The ecological solution of J2 Servid

It is an ECOLOGICAL system (available with FSC and PEFC certificate), reusable, foldable and recyclable.

Ideal system for road transport

Honeycomb

Made of cardboard and in the shape of a honeycomb, this innovative cargo void filler system is placed to fill the gaps between the pallets, as a separator, thus avoiding the movement of pallets during transport.

Custom manufacturing

Economic and effective solution

Niupack Categories

Discover the void filler that best suits your load

Niupack Top

VOID FILLER

Niupack Top

Niupack Large

VOID FILLER

Niupack Large

Niupack Side

VOID FILLER

Niupack Side

Niupack Double

VOID FILLER

Niupack Double

Union of two cargo void filler systems. Ideal to protect loose pallets in trucks and to gain longitudinal space in maritime containers.

Niupack Box

VOID FILLER

Niupack Box

Niupack Block

VOID FILLER

Niupack Block

Niupack Panel

VOID FILLER

Niupack Panel

The cargo protection system with padding consists of the use of materials to fill the gaps between the pallets. This is done to protect the merchandise during transport. This measure is especially necessary to prevent damage during movement and storage.

The filling of gaps between pallets helps to reduce the movement of merchandise during transport. This is done by using materials such as cardboard, foam, plastic pellets, bubble wrap, among others. These materials are placed between the pallets and adjusted to fill the gaps between them. This makes it possible to stabilize the contents and reduce the risk of the goods shifting during transport. This is especially important for fragile or high-value goods and ensures that no pressure is put on the goods and no vibration damage occurs. This is especially important for bulky or heavy goods that need adequate support for storage.

Our Niupack system is ideal for cargo protection.

The plastic degradation process is between 100 and 1000 years, while cardboard takes at most 1 year to degrade. Finding more sustainable, recyclable or reusable solutions to replace plastic, is one of the main objectives in the packaging market and the industry in general. That is why at J2 Servid we have launched the sustainable, reusable and recyclable Niupack.